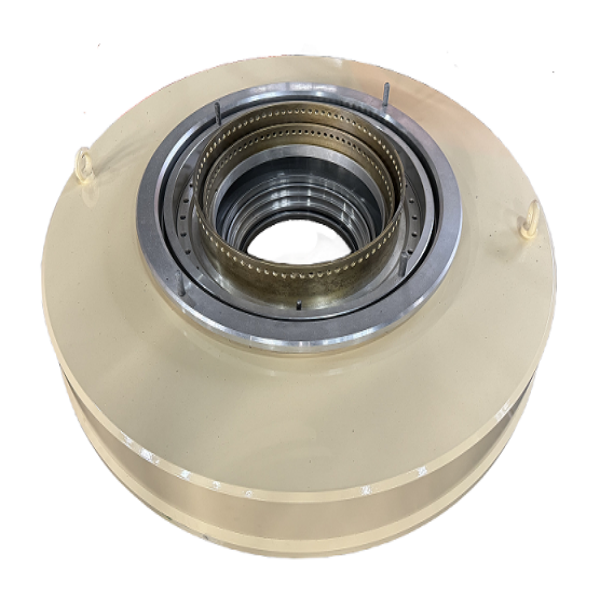

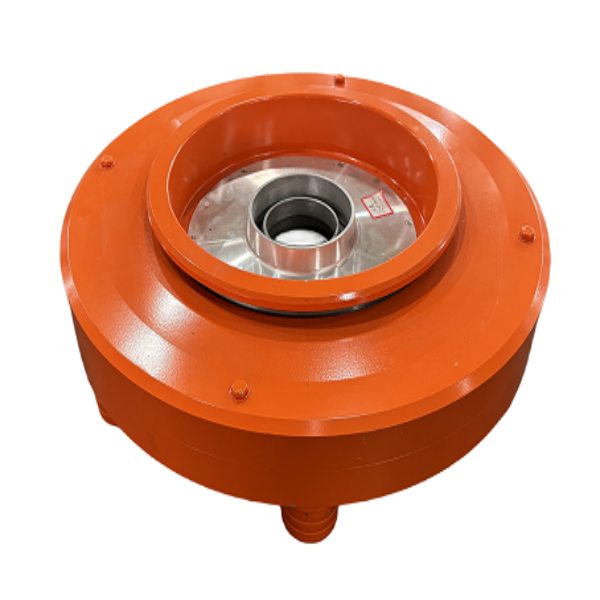

Film Blowing Machine Double Tuyere High Pressure Air Ring

1、Film blowing machine double tuyere air ring must go through a number of strict inspection processes, and the layers of inspection can be delivered. 2、The operation speed of the machine is orderly, adjustable, and the performance is stable. Widely used in various types of Film blowing machine double lip air ring. 3、The design is reasonable. Structure layout at a glance. Easy to operate and easy to use. 4、Film blowing machine high pressure air ring must go through a number of strict inspection processes, and the layers of inspection can be delivered.

Details

Film Blowing Machine Double Tuyere High Pressure Air Ring

1、Film blowing machine double tuyere air ring has two separate air outlets, and the jet ring is added to the upper tuyere, so the cooling effect is significantly higher than that of the single tuyere.

2、Film blowing machine double lip air ring is to cool the film bubble extruded from the die head and blown, and the cooling medium is air. At the same time, the airflow also plays a certain role in supporting the membrane vesicles.

3、Film blowing machine high pressure air ring is placed inside the membrane bubble to cool its inner surface by the hot air floating principle, which should be used with the inner cold die head.

4、Film blowing machine high pressure air ring, together with the on-line thickness measuring device and the computer information feedback control, constitutes the "IBC".

5、High quality aluminum alloy material is selected to forge into the rough embryo of each part of the mold.

6、Due to the difficulty of casting and the strength of cast aluminum, large air rings are welded with shell steel plate and embedded cast aluminum parts.